Sheet metal bending

Bending

Specification

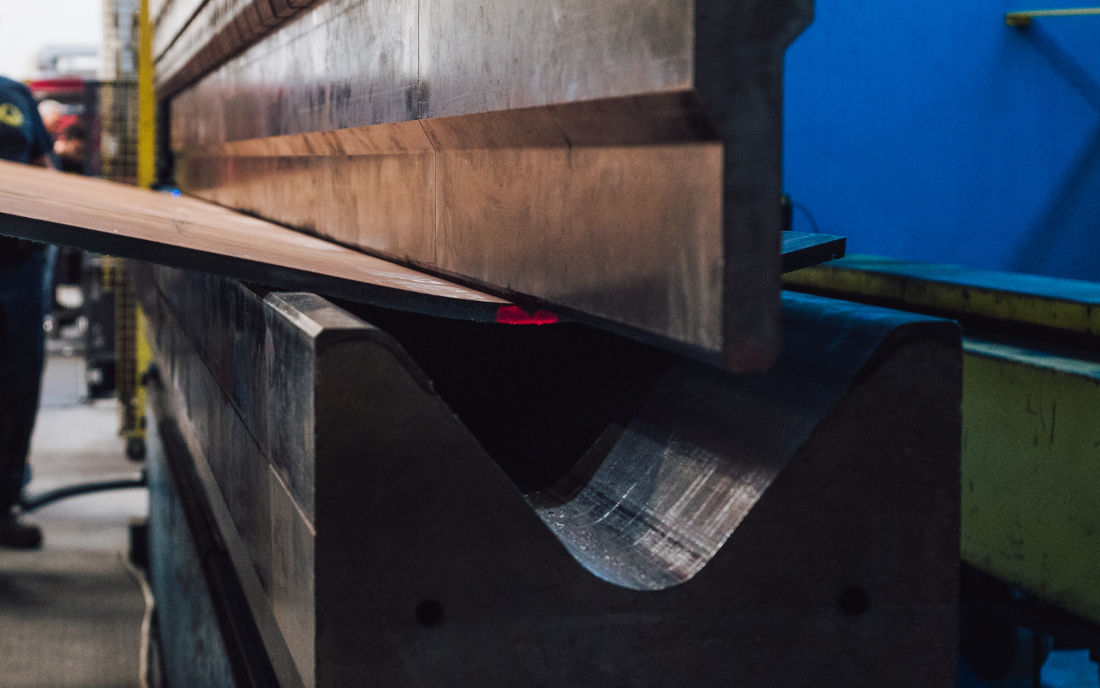

Sheet metal bending is the process that includes processing steps to give shape to the metal.

The bending of sheet metal for third parties and plates to drawings is one of the processes most requested by the market among those available at Compagnia Siderurgica, which allows the creation of semi-finished parts according to customer specifications.

Bending

Technology

The combination of the experience of our operators with updated 3D development software permits the creation of the part exactly to client’s needs, and after analyzing feasibility, permits the creation of bends with elevated standards of precision and accuracy even in the most complex designs.

- No. 1 bending press (1000 t). Useful work size: 7000 mm.

- No. 1 bending press (800 t). Useful work size: 6000 mm.

- No. 1 bending press (400 t). Useful work size: 4000 mm.

To complete the sheet metal bending department, Compagnia Siderurgica has a 500 ton straightening press, with a working area of 2500x6000mm, which guarantees perfect flatness of the cut parts and sheets, to correct any deformations.

Bending

Purpose

Customer satisfaction is our first goal. We carry out a bending process for third parties of proven quality, backed by over 30 years of experience in sheet metal processing.