Laser cutting

Laser cutting

Specifications

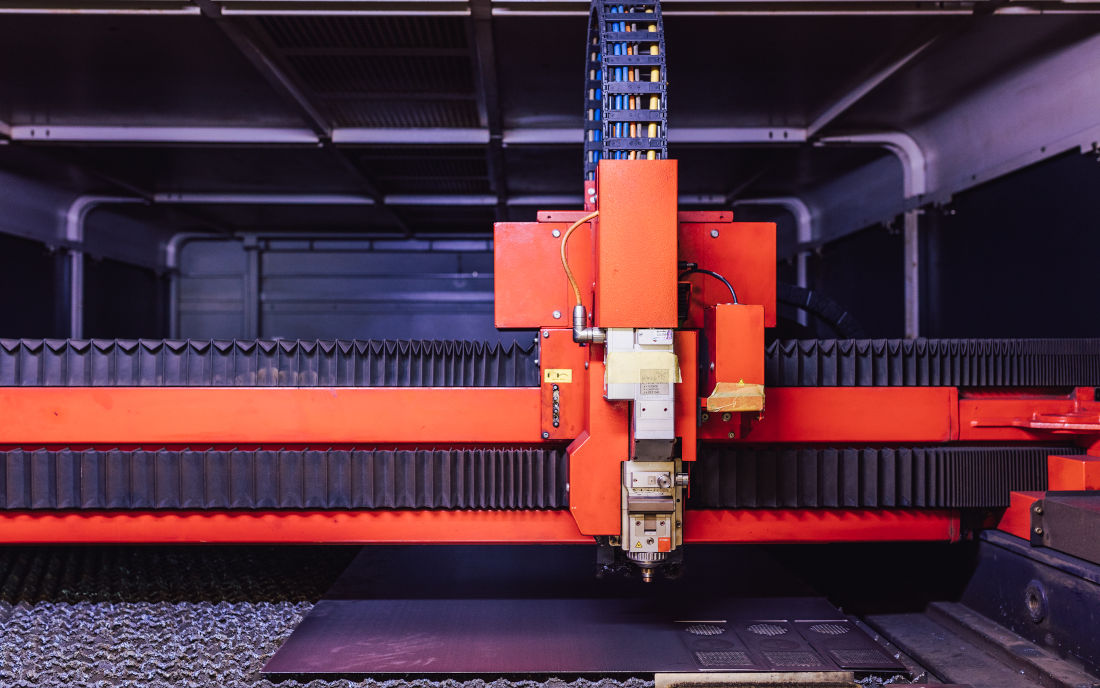

Laser cutting is the solution that combines efficiency and quality. This technique guarantees high precision, speed and versatility of use.

Compagnia Siderurgica, a Vicenza-based company specialized in sheet metal processing, guarantees the highest quality standards for this type of cut.

Experience in the sector is combined with the continuous search for modern machinery and efficient production in all aspects.

Laser cutting

Technology

Constantly committed to the technological upgrading of its machinery, Compagnia Siderurgica has recently added two fiber laser cutting systems to its laser department.

Both of them with useful working areas of 2000 x 4000 mm and automated loading/unloading systems capable of working thicknesses from 0.5 to 30 mm thanks to the powers of their respective 4 and 6 kW generators.

The quality of the laser beam offered by fiber laser cutting permits extremely high work speeds, especially at medium-low thicknesses (to 8 mm). The low roughness value of the finished product and the possibility to cut highly complex patterns permits the offer of pre-finished products that require no additional working.

Laser cutting

Purpose

The technology of fiber laser cutting, thanks to the quality of the laser beam, allows very high processing speeds, especially on medium-low thicknesses (up to 8mm).

The low roughness value of the finished product and the possibility of performing very complex geometries, allow to offer pre-finished products excluding any secondary processing.

Are you looking for a professional laser cutting service?